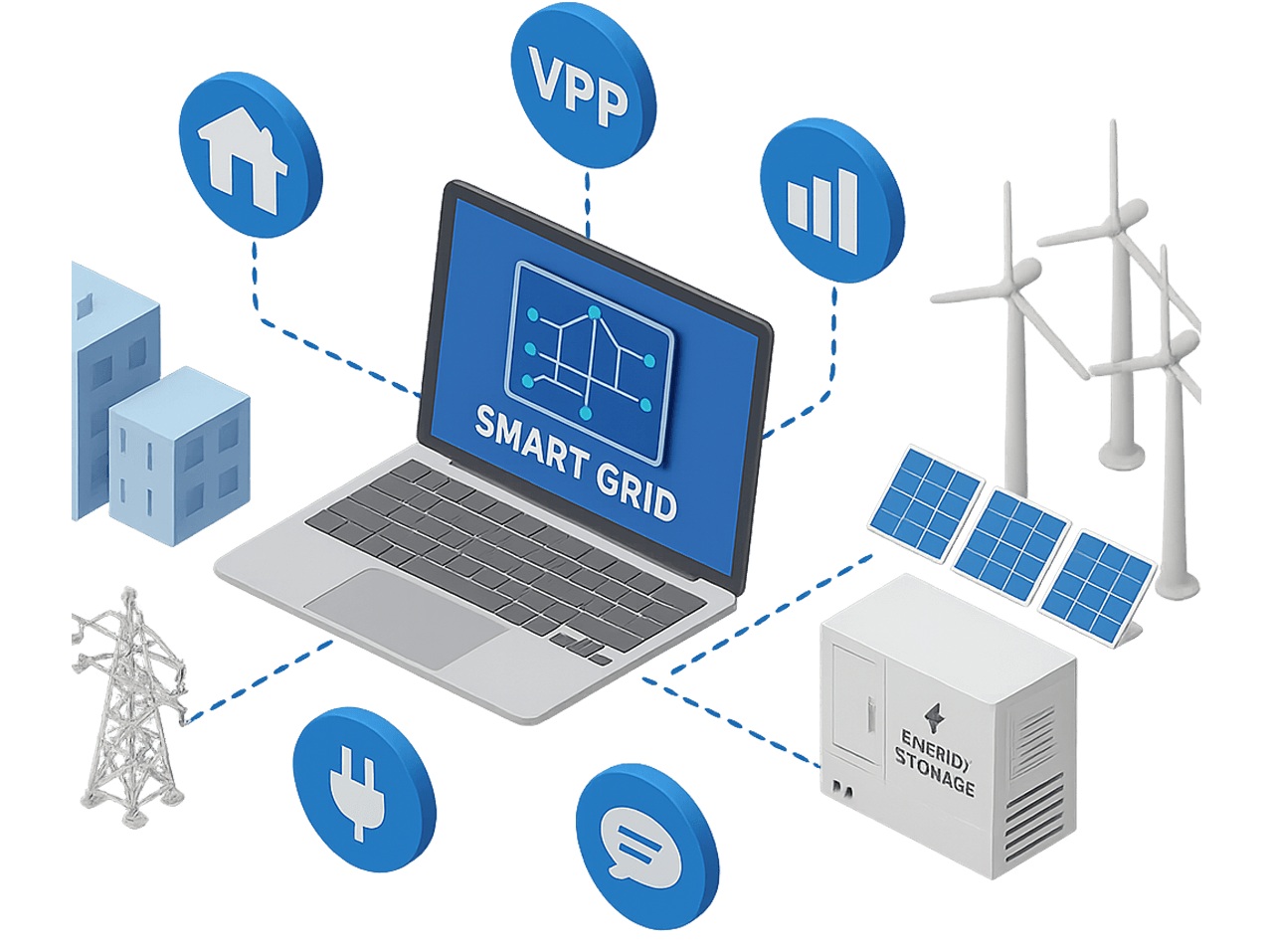

Smart grid / VPP

Integrate your devices into one intelligent system — lowering costs, boosting efficiency, and creating new revenue opportunities.

Worldwide shipping

We ship our equipment worldwide.

Contact us and we will solve any issue concerning logistics.

What Is a VPP and How It Powers the Smart Grid?

A Virtual Power Plant is a software-driven platform that aggregates, forecasts, and dispatches distributed energy resources (DERs) as if they were a single power plant. By combining advanced forecasting, optimization, and secure communications, a VPP turns intermittent or behind-the-meter assets into firm, market-ready capacity. In practice, it integrates with Energy Management Systems (EMS), Distribution Management Systems (DMS), and market gateways to deliver services such as frequency regulation, capacity auctions, demand response (DR), and energy arbitrage.

Why Smart Grid / VPP Matters

- Renewable integration: Smooths PV and wind variability using predictive dispatch and storage coordination.

- System reliability: Delivers ultra-fast frequency response, voltage support, and congestion relief at the edge of the grid.

- Peak management: Reduces demand charges and defers substation upgrades through targeted load shifting.

- Market revenue: Monetizes flexibility in ancillary services, capacity, and day-ahead/intraday energy markets.

- Customer value: Converts passive consumers into prosumers with tariff optimization and bill savings.

Core Technology & Standards

- Protocols: IEC 61850, Modbus TCP/IP, DNP3 for utility-grade telemetry and control; OCPP for EV charging; secure HTTPS APIs for cloud services.

- Forecasting & optimization: Weather-informed PV/wind forecasts, load prediction, BESS state-of-charge constraints, mixed-integer optimization for dispatch.

- Cybersecurity: TLS encryption, VPN tunneling for sensitive channels, role-based access control (RBAC), audit logging, and secure key management.

- Edge intelligence: Local controllers maintain safe fallback modes and islanding support during network outages.

- Scalability & interoperability: Modular architecture that spans from a single site to national portfolios.

Typical VPP Use Cases

- Demand Response (DR): Automated load reduction on DR events with verifiable baselines.

- Frequency regulation & FFR: Sub-second response via aggregated BESS and controllable loads.

- Peak shaving & TOU optimization: Time-shifted consumption and storage dispatch to minimize tariffs.

- Renewable firming: BESS-backed smoothing of PV/wind ramps to deliver predictable output.

- Local congestion management: Targeted dispatch at feeders and substations to avoid overloads.

- Microgrid coordination: Islanding, black start support, and resilience for critical infrastructure.

Economic Benefits

Smart Grid/VPP initiatives deliver a clear business case: they aggregate small, distributed flexibilities into market-scale value. Operators reduce balancing and network reinforcement costs, access diversified revenue streams (capacity, ancillary services, arbitrage), and increase the profitability of renewable projects by turning variability into dispatchable capacity. For commercial and industrial (C&I) users, the combination of BESS, PV, and tariff optimization cuts bills while improving power quality.

From China to Europe: Hardware + Software Supply

China leads global manufacturing of BESS, PCS, EMS, and EVSE, enabling cost-effective deployments at scale. Direct supply to Europe ensures:

- Competitive project pricing with tier-1 component sourcing;

- CE/IEC compliance and documentation for EU markets;

- Configurable portfolios from site-level BESS (0.1–5 MW) to utility-scale assets (10–100+ MW);

- Flexible logistics (EXW, CIF, DDP) and rapid rollout across multiple sites.

Implementation Blueprint

- Asset onboarding: Site audit, metering, firmware checks, cybersecurity hardening.

- Connectivity: Edge controller integration (IEC 61850/Modbus/DNP3/OCPP), secure gateways, data normalization.

- Modeling & forecasting: Weather, load, and price forecasts; SoC and thermal constraints for BESS.

- Optimization & dispatch: Objective-driven scheduling (cost, CO₂, revenue) with fail-safe local logic.

- Verification & settlement: Automated M&V, baselines, performance reports for market operators.

Who Benefits

- DSOs/TSOs: Reliability, congestion management, and non-wires alternatives.

- IPP & developers: Enhanced project IRR via stacked revenue services.

- C&I campuses: Bill reduction, power quality, resilience, and ESG reporting.

- Municipalities & campuses: Smart districts, EV readiness, and resilient public services.

⚡ In short, Smart Grid / VPP converts distributed assets into a firm, flexible, and monetizable power plant. It is the control layer that makes high-RES grids reliable and profitable—today.

FAQ — Smart Grid / Virtual Power Plant

1) What is a Virtual Power Plant (VPP)?

A VPP is a software platform that aggregates and dispatches distributed energy resources (DERs) to act like a single power plant.

2) Which assets can join a VPP?

BESS, rooftop and utility PV, wind, EV chargers, flexible industrial loads, heat pumps, and microgrids.

3) How does a VPP earn revenue?

Through ancillary services, capacity markets, demand response, arbitrage, and congestion management contracts.

4) What standards enable interoperability?

IEC 61850, Modbus TCP/IP, DNP3 for utility control; OCPP for EV charging; secure HTTPS APIs for market and cloud services.

5) How is cybersecurity handled?

Encryption (TLS), VPNs where required, RBAC, audit logging, and hardened edge gateways with secure firmware.

6) Can a VPP operate during outages?

Yes—edge controllers support safe fallback modes and microgrid islanding with BESS-backed critical loads.

7) How accurate is forecasting?

Modern platforms combine weather, load, and price models to reduce errors and improve dispatch efficiency.

8) What data is required from each site?

Real-time power/energy, SoC for BESS, inverter status, breaker states, and site limits; historical data for baselines.

9) How fast can a VPP respond?

From sub-second frequency response (with BESS) to minute-scale DR events, depending on market rules and asset type.

10) How can EU companies source VPP-ready hardware/software?

By procuring CE/IEC-compliant BESS/PCS/EMS and integrating with VPP software via standardized protocols and secure APIs.